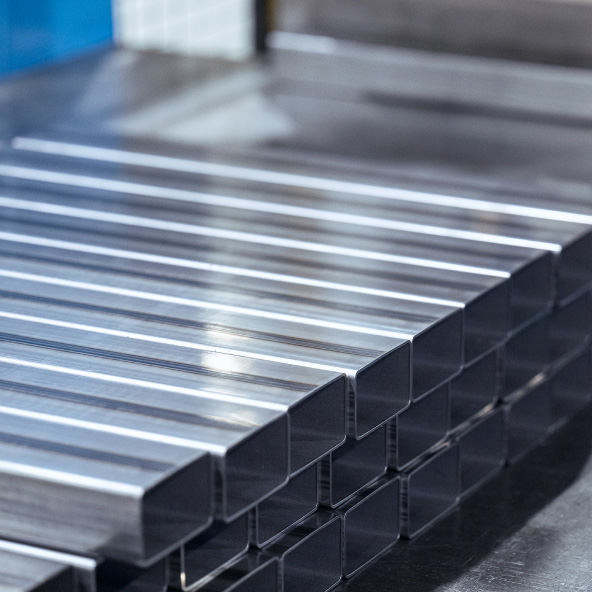

Cross cutting

Saw lines technical specifications:

- 2 Adige full automatic cutting line with integrated debburing and lenght control. Tube lenght 6,500mm. Cuting lenght 20-1,500mm, max ø80 mm.

- 2 Bianco 370A automatic bandsaw. Max capacity ø300 mm.

Value-adding tools

We want your business to prosper, so we’re happy to share our experience and add value to your project through engineering and innovation. For instance by helping you reduce the number of processes to cut cost, eliminate risk, and reduce emissions.

We do it through continuous investment in our 25 in-house processes, which meet an exceed all requirements of scale and complexity - from prototypes and single component production to small batches and regular mass production at different stages of completion.

Saw lines technical specifications:

Saw lines technical specifications:

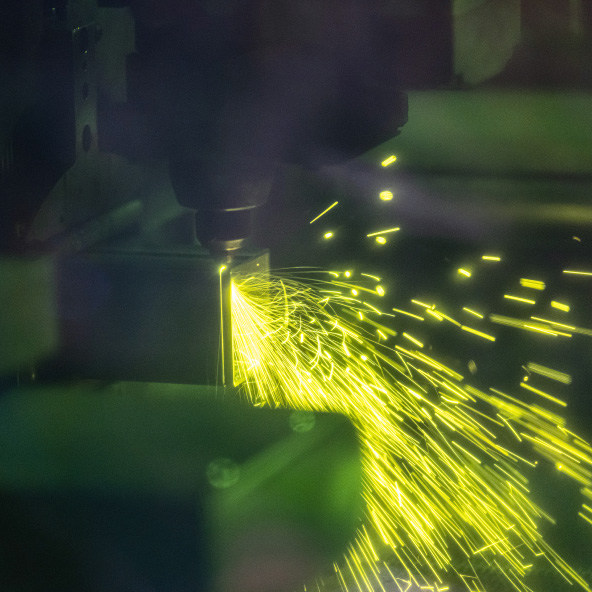

Fiber laser cutting technical specifications:

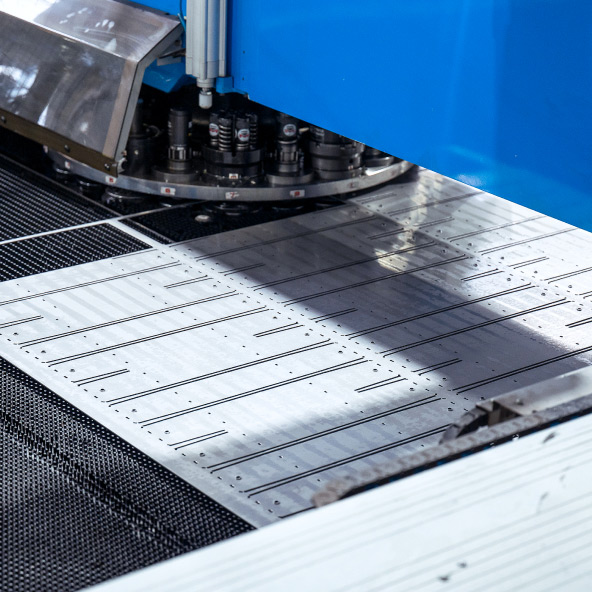

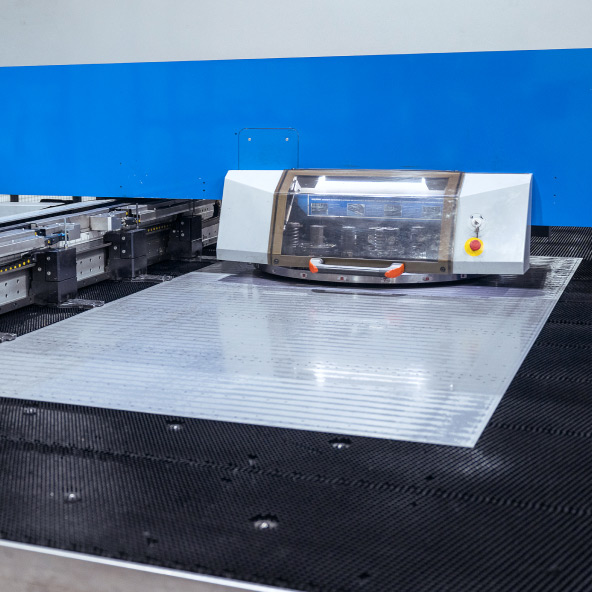

Revolver punching technical specifications:

Profile iron shears technical specifications:

Technical specifications:

CNC press brakes technical specifications:

CNC milling technical specifications:

Technical specifications:

Technical specifications:

Robotic welding specifications:

Technical specifications:

Automatic powder paint line:

Manual powder paintline complex:

Cleentek inline compo cleaner 1040 400x200mm

When we handle the assembly of your items in-house and on-site, you benefit from cost-effective production and simplified handling with reduced risk of damage and significantly lower production cost.

Our assembly department corrects minor faults and performs quality control according to your specifications, and we provide custom branding packaging and print manuals if needed. Fully assembled items can be delivered directly to client or end customer.

Technical specifications for tool manufacturing ovens:

Technical specifications for wire cutting:

Streamlined outsourcing efficiently compliments our in-house capabilities

Jensen Metal has a network of competent and reliable partners who provide the processes we do not have in-house. We evaluate our subcontractors regularly to ensure that they meet both our and your requirements at the highest standards.